With the increasing demand for engraving precision and efficiency, CNC laser engraver is more and more widely used in different industries. It prints the chosen diagrams perfectly and creates an effect of some depth, which distinguishes itself from ordinary ink printing. Be sure to choose the best china cnc plastic machining prototype to help you customize your goods.

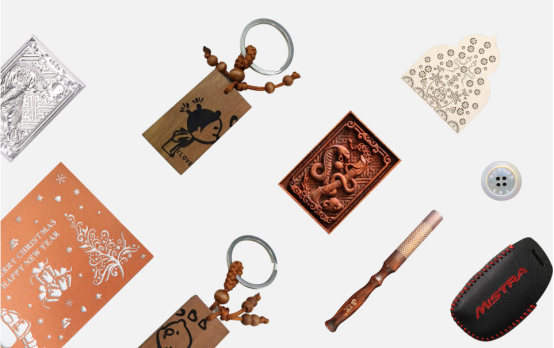

Thus it is an excellent tool for customizing like phones, pens, pencils, keys, wallet, watch, figurines, etc. So, how can we choose a laser engraver machine? Let’s get to know this step by step.

Laser engraver: how does it work?

High energy density laser is used to irradiate the workpiece locally. By this process, it makes the surface material vaporize or have chemical reactions that change the color, thus leaving the permanent marks. It used the advanced front focusing mode, adds dynamic focusing seat, adopts the principles of optics, etc. The focal length of the laser beam is changed to achieve accurate surface focusing and processing of different objects.

Different types of laser engravers

There are different types of lasers on the market. They are distinguished from each other by their laser sources. Here are the three most dominant types of laser:

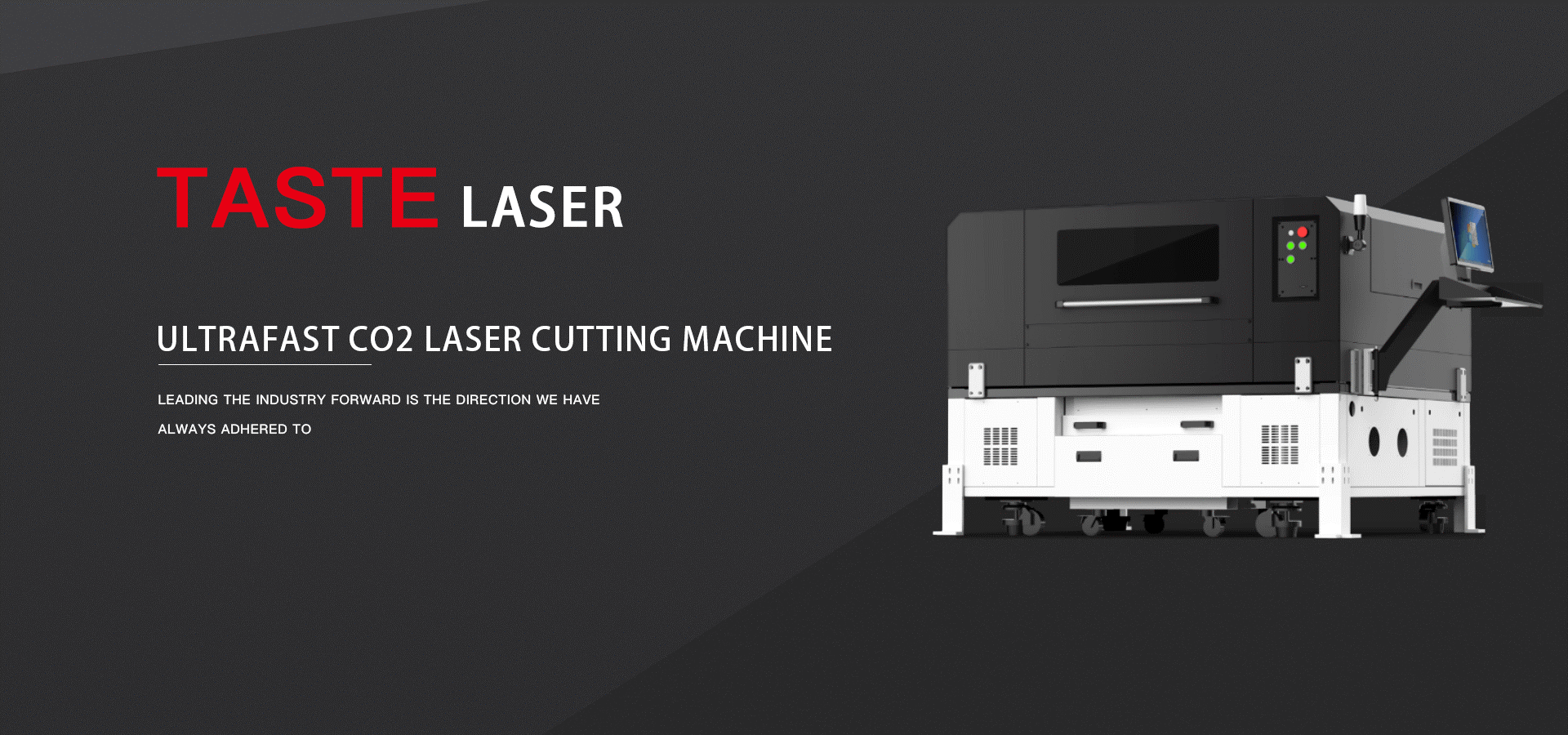

The gas laser or CO2 laser. They offer excellent quality beams and are generally used on non-metallic supports. Thus, they can be used on wood, paper, leather, plastic, stone, acrylic and textiles. ModFrom simple writes to complex diagrams such as logos or other emblems, the laser engraver can print with absolute precision all desired patterns.

The fiber laser. In comparison with the first one, this type of laser releases a power a hundred times more intense. The etching time can last a very long time: up to 25,000 hours of use more than the CO2 laser. The fiber laser seems better suited for printing on iron, metals or resistant plastic.

The crystal laser is classified among the most solid lasers. Indeed, crystal lasers are able to print on metal, reinforced metals, plastics and even ceramics. The crystal laser has a lifespan of 8000 to 15000 hours. Its diodes will, therefore, be replaced after 15,000 hours of use, which is significantly lower than a fiber laser.

Must-know tips on choosing a laser engraver

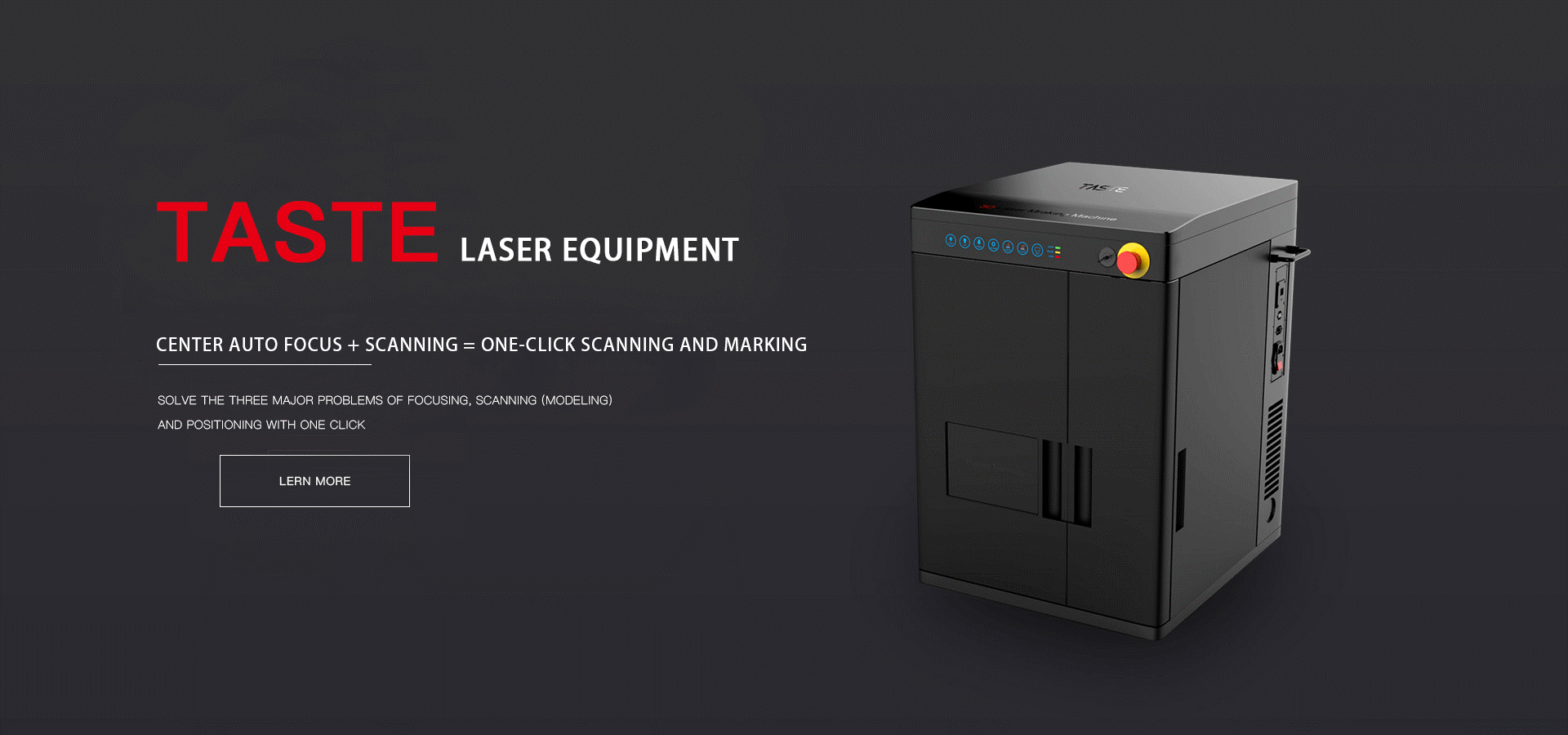

Engraving accuracy. The most significant difference between laser engraver machine and traditional engraving equipment/hand engraving is the engraving precision. The requirement of engraving precision is relatively high for delicate projects/drawings. The TASTELASER CO2 laser marking machine is a good example. With dynamic focusing large-span technology, it has integrated more extensive effective coverage, a higher degree of fineness and better uniformity. It can truly achieve high power engraving while ensuring accuracy.

Laser power. For some materials like stone, wood and other harder ones, higher power laser tube will be required for the excellent working performance. On the contrary, big power laser tube is not necessary for some materials like acrylic, double-color plates, etc. If your workpieces vary from fragile material to coriaceous ones, consider more on uniformity.

Machine quality. Laser engraving machines of even the same appearance have quite different parts and further different variety. Main things to compare is the stepper motor, laser lens, laser tube, machine bed, apparel, leather and engraving speed. For example, TASTELASER CO2 laser marking machine applies a unique folding cavity design to help achieve better beam quality. It also provides smaller spot diameter, more excellent product effect, excellent uniformity and high consistency. As for the machine bed, it has used an adsorptive platform to make the object close to the working plane and prevent it from position deviation. Meanwhile, the exhausting system can better absorb smoke and dust, ensure the stability in the continuous marking process. With the exclusive design of big scanners, it is more efficient and cost-effective than ordinary laser equipment.

The appearance of the new 3D laser marking machine has solved the long-time inherent defect of the 2D laser marking machine. A piece of quality laser equipment can save the endless testing and adjustment that an improper laser engraver may bring. Take your time and have a closer look at multiple types of product!