Because most of the overhead transmission lines run in the field, it is not easy to be monitored by a human in time, and the impact of bird activities is relatively significant. The accidents such as short circuit and trip caused by birds nesting and perching on the tower are increasing year by year. This not only makes the operation and maintenance units suffer high losses of human and material resources, but also seriously threaten operation of the power grid. That’s why a bird flight diverter is invented.

To ensure the safety and stability of power transmission lines, all power departments use different equipment to assist in bird prevention. Today we will try to gain a basic understanding of a bird flight diverter.

What is a bird flight diverter?

A Bird Flight Diverter is specially designed for application on overhead conductors, creating greater visibility for avian flight paths on overhead lines as well as the down guys. It cuts down hazards to both lines and birds because of the little wind resistance it offers. For low and medium voltage construction, you could apply the Bird Flight Diverter to divide conductors (bare or jacketed). On the contrary, for high voltages, it is typically used on shield wire.

The Bird Flight Diverter is lightweight, offers little wind resistance, and is easily and quickly applied by hand or hot stick. The positive grip on the conductor is designed to ensure that the Bird Flight Diverter remains in the affected location and does not move along the span under Aeolian vibration or other conditions.

The materials used to make a bird flight diverter:

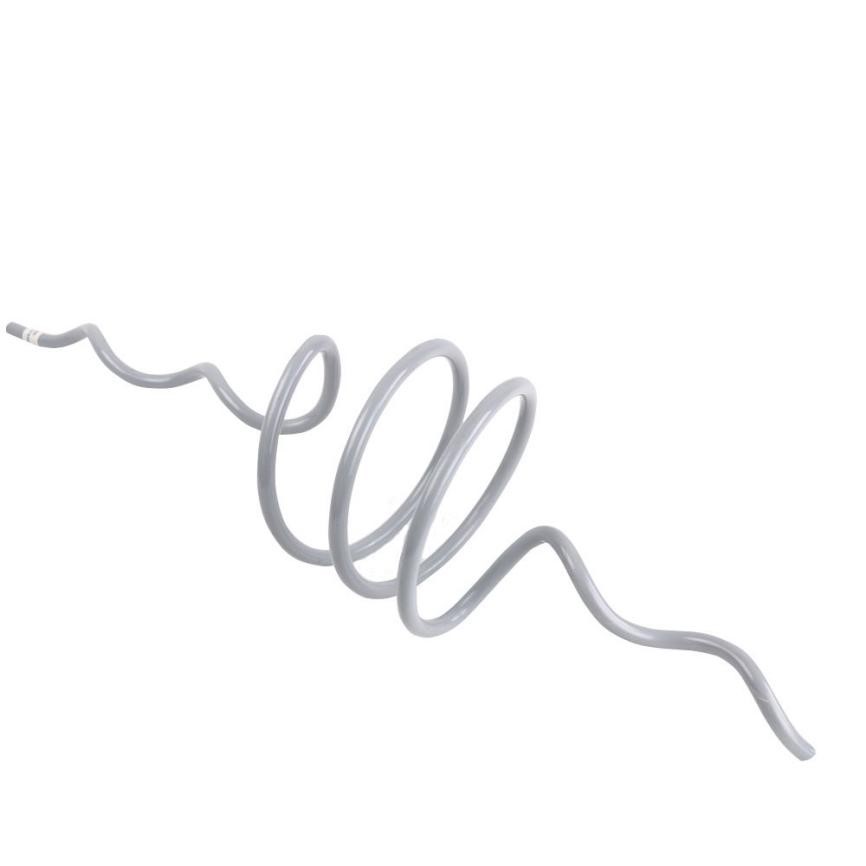

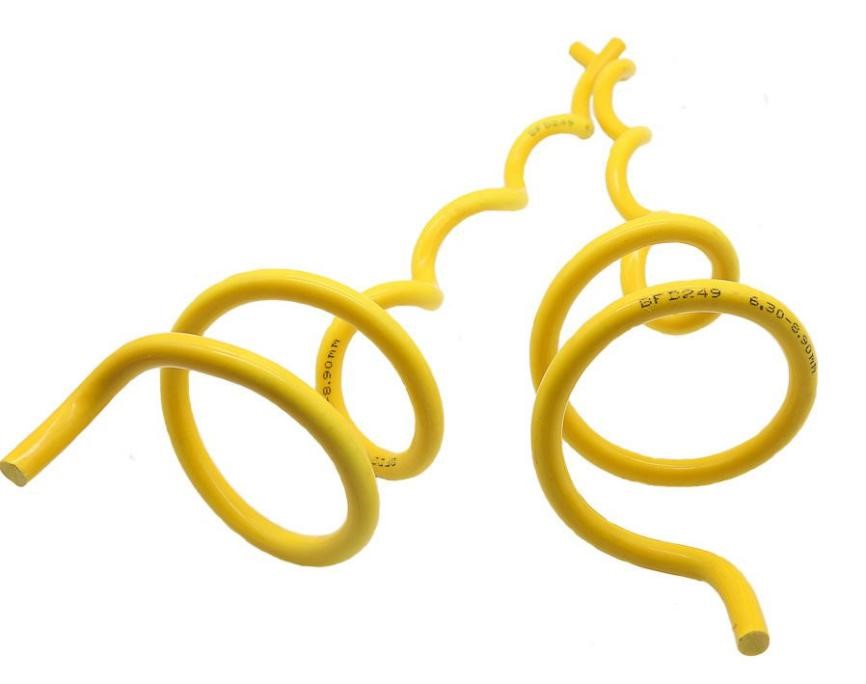

Manufactured from rigid high impact polyvinyl chloride (PVC), the Bird Flight Diverter possesses excellent chemical resistance, strength properties and retains good physical characteristics within a range of extreme temperatures. Industrial fumes and salty water cannot seriously degrade the properties of rigid PVC.

The spacing of a bird flight diverter:

For optimal results, spacing distances are generally recommended at 15′ intervals, depending upon local conditions. Since wind resistance is minimal, sufficient Bird Flight Diverter can be used to ensure adequate visibility without creating stresses on the line. When marking adjacent spans, overall visibility is improved by staggering the placement between the spans. Features Bird Flight Diverter is designed to offer the following advantages:

- Increased conductor profile to provide increased visibility where large, slow-moving bird flight paths are present

- Economical and easily applied

- Lightweight

- Long service life without deterioration of material properties

- Minimal wind resistance

- Manufactured from gray or yellow high impact PVC with UV protection

The visibility of a bird flight diverter:

The diverter section increases the visible profile of the cable or conductor to ensure safety but avoids an undesirable bulky outline. The application provides the correct size Bird Flight Diverter is used. For a detailed installation description, refer to the application procedure. Hot stick application is fast and straightforward with standard equipment.

Recommendation:

Henvcon Electric Power Technology Co., Ltd is a professional manufacturer to produce preformed electricity cable fittings, wire fittings, line fittings as well as bird flight diverter. The company runs in the fields of electric power, telecommunication, railways for more than seven years and immense experience in various projects has been accumulated.

The bird diverter they manufacture is made from gray or yellow high impact PVC of lightweight and minimal wind resistance. They could be easily and quickly installed by hand. The positive grip on the conductor ensures the BIRD-FLIGHT Diverter remains in the applied location. They also have a long service life without deterioration of the material.

In a word, the bird flight diverter is essential to protect the electrical usage.